RFID tags and label products are becoming increasingly popular for warehouse management as a way to maintain control of your inventory.

What is RFID?

Radio-frequency identification (RFID) uses electromagnetic fields to automatically identify and track tags and labels attached to objects. The tags and labels can contain large amounts of electronically stored information. Passive tags or labels collect energy from a nearby RFID reader’s radio waves. Active tags and labels have a local power source (such as a battery) and may operate hundreds of feet from the RFID reader. Unlike a barcode, the RFID tags or labels don’t need to be within the line of sight of the reader, so they may be even be embedded in the tracked product or container.

How do RFID Tags Benefit Warehouse Management Operations?

RFID tags are used in many industries. For example, an RFID tag or label attached to a product or container can be used to track its whereabouts throughout the time spent in a warehouse. The accurate location tracking using RFID makes warehouse management more precise and efficient. In addition, RFID technology provides greater visibility into inventory management as products move within the warehouse and across the supply chain.

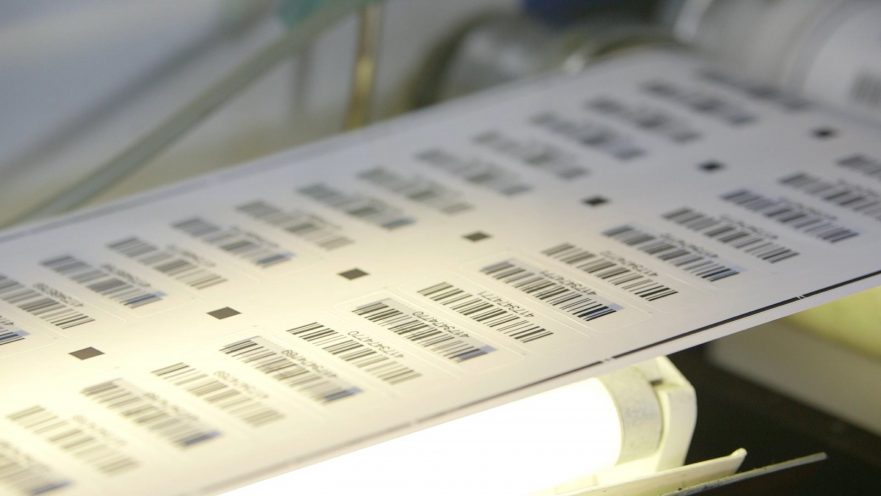

In warehouses, distribution centers, and facilities that have deployed automated inventory management technology, barcode labels have become standard operating procedures. However, RFID tags and labels are quickly becoming a larger part of the inventory management equation. Think about the retail industry for example, where massive amounts of product are temporarily stored and/or pass through warehouses on their way to retail stores. RFID tags or labels can track products at the pallet, case, and even item-level in the warehouse.

Additional Benefits of Using RFID Technology

RFID tags and labels do not require line of sight for scanning compared to barcode labels where employees with hand-held scanners, or fixed position scanners have to see the label to get a successful scan. For example, in conveyor-based or lift-truck operations, boxes have to be oriented a certain way on the belt so that the barcode label can be scanned. Because RFID tags and labels can be read from any orientation, using RFID tags and labels speed up the scanning process and reduce the labor associated with repositioning boxes for scanning. Scanners can also read multiple tags or labels at the same time, so an entire pallet-load of items can be scanned simultaneously.

Implementing an RFID tag or label warehouse management system can reduce labor costs as well. Labor can account for 50% to 80% of costs in a warehouse/distribution center. With RFID tags and labels, inventory check-in, inventory counts, picking times, and shipment verification can all be completed in seconds. RFID tags and labels are made to be scanned in groups, meaning that many assets can be scanned at once, reducing the manual labor aspect of individually scanning every item.

In many cases, warehouse processes that used to require multiple employees to complete using barcodes and scanners can be handled automatically with just a few scans using RFID technology. Furthermore, in some studies, RFID systems are capable of reading an entire warehouse of inventory in a matter of minutes, effectively reducing the inventory management process from days and weeks down to hours.

RFID technology also improves accuracy of inventory location by providing real-time updates and faster scanning. With RFID readers placed strategically at the doorways and throughout the warehouse, managers and their customers can know exactly when inventory enters or leaves a location. With barcodes, employees could potentially move an item without scanning it, leading to diminished inventory accuracy.

Can RFID Tags and Labels Track Reusable Containers?

For companies that use returnable containers or pallets, RFID tags and labels provide a way to track those assets throughout the warehouse and across the supply chain. RFID technology can reduce loss or theft of the assets as well. In many cases, returnable/reusable containers can represent millions of dollars in capital investments. RFID tags and labels provide a cost-effective means to reduce those expenses.

Still Have Questions About RFID Tags and Labels?

The Kennedy Group is here to make sure your RFID tag or label products meet your company’s unique application and requirements. Contact us today with your challenges and questions. Let us know how we can help match your needs with our state-of-the-art, high-quality RFID products. Our in-house RFID lab experts will help identify the correct type of tag or label and assist in determining the best software and hardware for your use.